Routledge, the publisher of the manuscript "The Toyota Economic System", published the book unedited and made errors replicating several of the figures and tables. Below is a list of the corrections.

This situation is unfortunate and out of the author's control. Consequently, the author has requested that the sales of the book be halted. He has terminated his relationship with the publisher and re-acquired the publishing rights. The book will be re-published as a new edition using a different publisher.

If you have purchased the book and are unable to return it to Routledge or Amazon, please contact the author at olarue@ydatum.com

Finally, if you noticed errors, we would appreciate if you would communicate them to the author via email at

olarue@ydatum.com

Our sincere apologies for the confusion and inconvenience.

Introduction page XVII

Fourth bullet says: "it does not abandon mass production."

Please see correction.

It should say: "it does not abandon economies of scale."

Page 54:

This paragraph reads:

The simplicity of the definition can be deceiving. We must closely consider the definition in the context of continuous flow, which includes volume quantities, number of product types varieties, and location of order acceptance coming from the upstream process.

"coming from the upstream process" is not correct.

Enter text

This paragraph should read:

The simplicity of the definition can be deceiving. We must closely consider the definition in the context of continuous flow, which includes volume quantities, number of product types varieties, and location of order acceptance in the upstream process.

"in the upstream process" is correct.

Page 70:

Second to last sentence on second paragraph says:

"An order of three circles and four squares scheduled in a batch will only incur two changeovers instead of eight."

Eight is wrong, it should say seven.

Please see correction:

"An order of three circles and four squares scheduled in a batch will only incur two changeovers instead of seven."

Page 73:

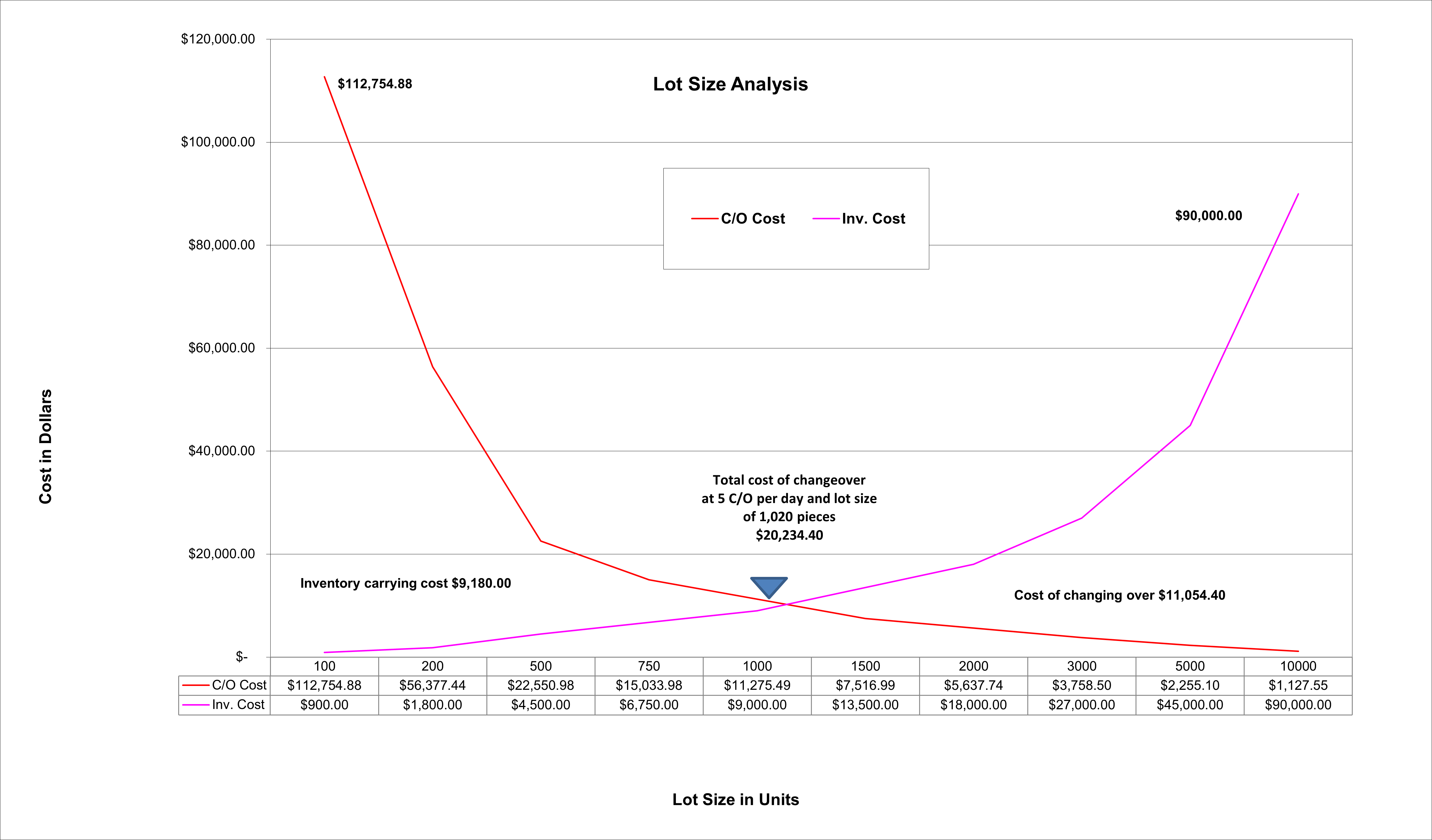

The EOQ figure 4.14 is incorrectly replicated. Please see the corrected figure.

Additionally, understand that the number of changeovers per day must be a whole number. It is equal to 5 changeovers per day in the example. Consequently, the changeover cost and inventory carrying cost are not equal.

The cost of changeover and the inventory cost are equal when we perform 4.5 changeovers per day which is not possible.

Page 104:

The shift schedule is incorrect:

Please see corrected shift schedule.

Let’s now look at a simple example of using takt time to calculate and evaluate the resources needed. Imagine that customer demand is 460 units per day, and we have one production shift starting at 6:00 AM, finishing at 2:30 PM with 30 minutes for lunch and two 10 minutes breaks. This means that we need to produce 460 units per day during 27,600 seconds of available production time. Dividing the available work time of 27,600 seconds by 460 units of demand per day, we find that we must complete a unit every 60 seconds.

Page 112:

Title says: Pull system, the second element of just-in-time. It is incorrect the pull system is the third element of just-in-time in the house of TPS.

Please see corrected title.

Pull system, third element of just-in-time.

Page 133:

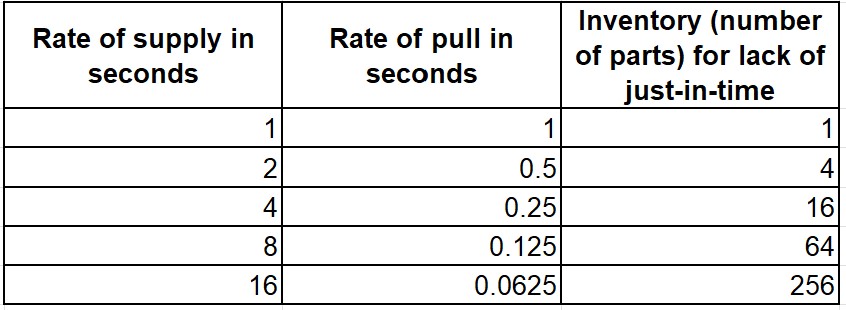

Table 4.5 is incorrectly replicated:

Please see corrected numbers in the column "rate of supply in seconds" in the corrected table.

Page 173:

The denominator in the example of the weighted average cycle time is incorrect.

The denominator is the sum of the demand and equal to 461 (not 450)

Please see corrected equation.

WACT = ((55 x 160) + (60 x 153) + (65 x 148)) / 461 = 60 seconds